Do you know what Kanban is? Let me tell you about its history-EN

Iria Rivero

- Business Agility

- Article

In times of uncertainty and crisis, it is especially difficult to find opportunities. However, although it may seem paradoxical, sometimes it is where the best solutions are created. That is the case with Kanban.

Let’s put it in context.

Japan, 1945. A country devastated by war, drowning in defeat, and with an economy and industry based on war.

In these circumstances, it is hard to imagine how companies could embark on a path of reconstruction, but only a few were clear about one thing: to become competitive, they had to do something different, and to do so, they had to try the path of reinvention.

It was then that the Japanese Union of Scientists and Engineers was founded in 1949. With Masaaki Imai at the head, a new concept emerged: Kaizen (Kai: change, Zen: goodness, something good or better).

He hypothesizes that to be competitive, they need to improve as much as possible, adjusting resources to the maximum and focusing on delivering value to the customer. There is always room for improvement, so more than a method, it is a philosophy carried out every day, not only in the workplace, as it transcends into all areas of life.

¿What is Kaizen philosophy?

The Kaizen philosophy is a constant search to reduce, transform or eliminate those elements that give us little or nothing and what we call waste.

In this search, many questions arise, what brings value? What are our needs? And those of our customers? What about those of our organization?

And, of course, how can we achieve it before anyone else?

If we can identify the elements that we call waste and put them aside, we can focus on those that add value more quickly and with higher quality.

To do this, we have to involve all the participants in this process, make people see the need for continuous improvement, having courage and nonconformity as the necessary levers to do things differently.

It was in this context that, Kanban was born within the framework of the Toyota world.

The 1940s were a challenging decade for the Japanese industry. In addition to being in the middle of the post-war period, they had a competitive disadvantage compared to the American industry based on productivity.

They did not have the resources to invest, so they had to reinvent themselves. The first step they took was to start observing what they were doing.

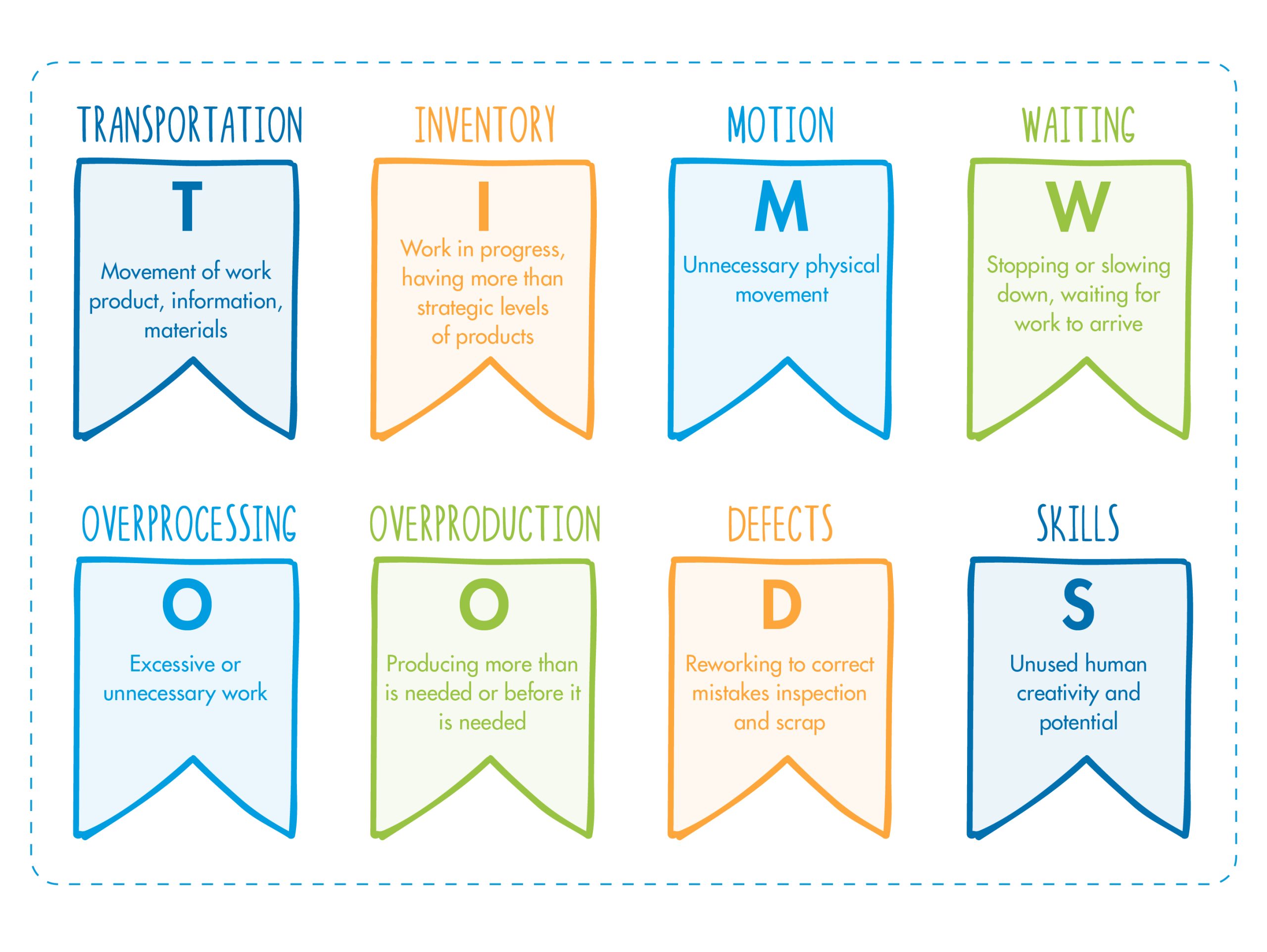

Eight types of waste

As a result of this observation, Taiicho Ono classified the eight types of waste in his production chain: transportation, inventory, movement, waiting, overproduction, overprocessing, defects, and wasted talent. He was able to identify where waste was occurring, i.e., where in his chain there were resources or work was not efficient or even ended up in the trash. Knowing their points of improvement, they made decisions to minimize them.

They focused on producing what was needed when it was necessary and required. In production systems (and in any workflow), there can be a push or pull system, i.e. systems where you produce something and then try to place it on the market or systems where you only produce what the end customer has ordered.

As a result of having to produce what they needed, they included a system of cards through which they could follow the demand in their factory, and this is how the Kanban philosophy was born.

Operators could only work with a limited number of Kanban cards which were allocated to a product from start to finish. When that product was finished the Kanban card was released, and a new product could be assigned.

By doing this, they could visualize the workflow, know what materials they needed at any given moment, see where bottlenecks were occurring, and concentrate on finishing a product before starting a new one.

That is one of Kanban’s maxims: stop starting and start finishing.

This method, which was born as an experiment, was then refined and generalized.

They used the scientific method to mark their next steps.

But how did Kanban make the leap from an industrial process to other sectors?

With the birth of the agile manifesto, the software world began to speak with other words, such as rapid delivery of value or welcoming changes in requirements by being more flexible. The leap from software to other areas was not long in coming, and today agile principles are used in all types of organizations. Kanban offers a way to visualize, control, understand, and make the work of many teams more effective.

Kanban principles and practices

All this philosophy is materialized through the Kanban principles and practices, which begin to ground how this system works.

There are three principles of change management:

- Start with what you do now: we should not start with anything disruptive. The first step is to observe and then make changes one by one to measure their effects.

- Accept the incremental evolutionary change: it is important to agree on improvement steps and do them little by little to avoid resistance when implementing them.

- Encourage acts of leadership at all levels: we are looking for empowerment and collective intelligence, much more powerful if it comes from everyone in the organization and is not only expected from its management layer.

There are also three principles of service delivery:

- Focus on customer needs and expectations: the customer is at the center of every action, so we focus on understanding and exceeding their expectations.

- Manage the work, not the workers: self-management of teams is key in service orientation, leaving aside micromanagement.

- Periodically review the service network: the system must be reviewed on an ongoing basis; it is alive and must be different over time.

It is based on six practices

Kanban allows us to visualize many elements by making them tangible. Difficulties and blockages emerge so changes and decisions become more urgent. It is essential to go step by step, as you will only see the effect of decisions if you take them one at a time.

The process is to see, analyze, implement a change, and measure it. After all, the scientific method and continuous improvement are part of its DNA.