What’s SAFe® House of LEAN?-EN

Iván Martín Bermejo

- Project Management

- Article

The LEAN HOUSE is one of the classic schematizations of LEAN thinking, which shows at a glance how LEAN MANUFACTURING was experienced at Toyota before the rest of the world began to know it as LEAN, during a time when the company implemented the TOYOTA PRODUCTION SYSTEM (TPS).

It has always struck me that this method is referred to as ‘house’ and not ‘door’. It may be that in our Western eyes, this structure reminds us of a classical Greek temple, but I would like to think that a Japanese sees a torii, so characteristic of their Shinto-influenced culture in this figure.

LEAN HOUSE

What we see is a schematization of the main principles of LEAN thinking. This is one of the most classic visions:

From the bottom up, we see a statement

of intent at the base: the foundation of the Toyota production system is stability. What stability means at Toyota is what is indicated at the next level:

-

Heijunka, which implies demand control: ‘answering’ from our factory a level of demand aligned with our production capacity. It does not contemplate putting the machines at total capacity, nor is production incentivized with a merely quantitative objective.

-

Standardized Work. With the level of demand and the production target aligned, we work with well-known, safe and predictable practices to maintain stability.

-

Kaizen. Toyota understands that for a system to be permanently working, you must constantly improve it. Just as if you want a ship to stay afloat, you cannot leave it still in the harbor, at the

mercy of the salt and corrosion of the water, but you must constantly be making minor repairs and maintenance tasks. It is constant change that prevents degradation. Continuous improvement is what keeps us stable.

And how is this done on a day-to-day basis? The two pillars of the ‘house’ are the two keys to the operation of what we later came to know as LEAN MANUFACTURING.

Just in time production:

-

It always responds to customer demand (pull) leveled by the Heijunka.

-

The same work rhythm is maintained (takt time) thanks to standardized work,

-

And there are no interruptions or variability in the flow of activity because Kaizen has taken care of eliminating all waste.

The importance of human control, or jidoka, is synthesized into two principles:

-

In LEAN production, a specific place is given to automated work subordinated to human control.

-

In case of an error or an abnormality,

the person who detected it stops the chain, and an immediate on-site attention

procedure is activated – the Japanese would say Gemba – which tries to solve

the case in less than 2 minutes.

If this is unsuccessful, it is removed from the chain to avoid harming the other elements in progress (WIP). This ensures that no defective part is produced, that no work is done in vain, and that a glass or an engine is not wasted on a useless chassis.

In addition, the error is studied to find the root cause and eliminate it. When necessary, a strategy is adopted to make the system ‘fail-safe’. In Japanese, a poka-yoke is added.

The ultimate goal is at the top:

-

Maximize quality.

-

Reduce cost (due to waste).

-

Reduce manufacturing time.Maximizar la calidad

Watch out for the latter! Nobody wants (in a LEAN thinking scheme) that a car leaves the factory particularly fast, but that the chain’s pace can be improved, in a stable way, as we reduce waste or inefficiencies.

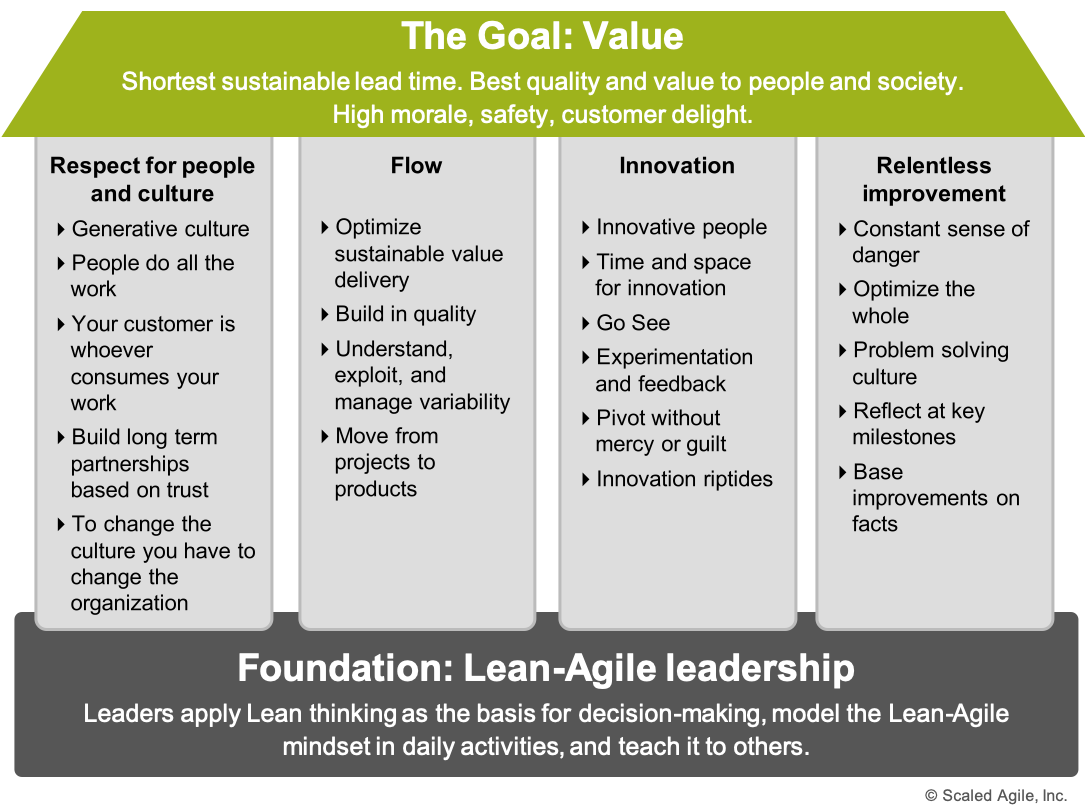

SAFe ® HOUSE OF LEAN

There are many variations of this LEAN HOUSE. Many authors have complimented the above by adding the people factor or management issues; others have incorporated TPM (Total Preventive Maintenance) or the 5S…

In my opinion, one of the most valuable ‘modifications’ is the SAFe ® HOUSE of LEAN, which involves integrating the principles of an agile mentality with traditional LEAN thinking.

This is the result:

And these are the main additions:

Leadership is the new foundation of the house.

This is perhaps the most critical change and lies in the most profound difference between LEAN thinking and the Agile mindset. LEAN is a model that applies to a factory, a set of processes and jobs that work together as a unit. That is why the base of the LEAN HOUSE is the stability of that whole.

Agile conceives that the value for the customer is produced through several teams working autonomously. What is the base of these teams? In an Agile or SAFe® model, the leaders or decision

centers are the ones who radiate the organization’s mindset to the others.

New concepts are incorporated to get the job done

In a more or less implicit way, LEAN HOUSE has already exposed concepts such as Respect for the Individual, variability, flow, on-the-job experimentation, continuous improvement and problem-solving. However, there are some exciting additions to the pillars:

-

Culture. In agile, culture is a concept that, while intangible, is part of the cohesion between necessarily autonomous teams. In many ways, it is both cause and reflection of the leadership style we have established as the house’s foundation. That is why in this SAFe ® HOUSE of LEAN, it is essential to dedicate a space within the pillars to achieve the goal.

-

The product concept. We are familiar with the transition between a Project Manager and a Product Owner in the Agile mindset. A project is planned, and a future state is defined from the beginning.

However, in the Agile mindset, you build products that work and move towards delivering value that satisfies the customer. In the SAFe ® HOUSE of LEAN, we have to understand that what will

“flow” are not the elements resulting from a planned assembly line but products that are tested with the customer to keep iterating them until they meet their needs.

-

Constant innovation. The scope for innovation in LEAN thinking is limited to how things are done, which is under continuous improvement.

However, in this SAFe ® HOUSE of LEAN, we find that innovation is a fundamental pillar because we also innovate in terms of what we will do.

The challenge of customer value comes without explicit instruction from the vehicle transporting it. Therefore, new solutions must be experimented with. Probably the greatest contribution people can make.

The goal is stated to be much more ambitious

The goal of the SAFe® HOUSE of LEAN includes the purpose of its LEAN thinking forebears. Maximize the quality and make it possible to maintain the fastest possible pace of work over time.

However, it allows itself to go further with some concepts that, without hesitation, prove to be more ambitious:

-

Customer value is extended with a perspective of society as a whole. This must connect with a more profound concept of culture, such as the one in this scheme.

-

We must not only satisfy the need expressed by the customer but also give him a higher emotional stimulus that makes him ‘fall in love’ with what we offer. In the Product conception we have mentioned, we go beyond the mere response to some requirements and connect with implicit customer needs. It is also an embryo of what could be a more recurrent relationship based on services.

-

It considers the company’s employees’ perception, their morale, motivations, and whether they feel secure… This is very important when we are asking them to deliver innovative solutions.

The SAFe ® HOUSE of LEAN’s way of describing the principles of any organization is a valid guide for a context of transformation towards Agility and in response to the Digital Transformation that most companies face today, regardless of their size, the sector they belong to and the more or less intensive use they make of technology.

This model considers all the necessary dimensions and provides us with action tools to implement them directly.